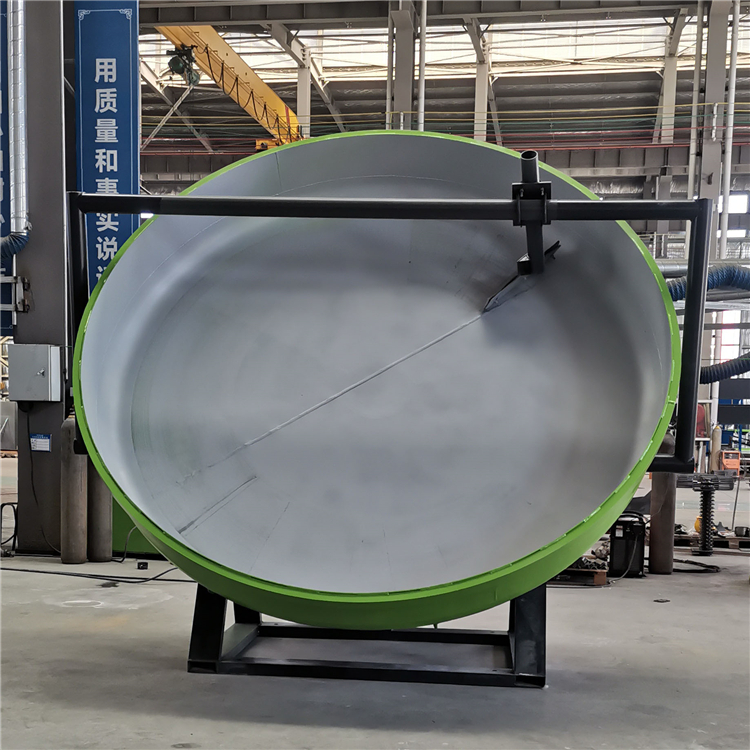

圓盤造球機 Disc Balling Machine

圓盤造球機用于鐵礦粉造球,它是各類球團廠的主要配套設備之一。圓盤造球機是在吸收國內外先進經驗后設計研制而成的。產品采用電動旋轉刮刀刮盤面撥粒造球,適應性強;傾角和轉速均可調;結構形式為簡潔的逆流式,安裝方便,易于維護;生產能力強,效率高,產量大。主要技術指標在國內已達到領先地位,并占據80%的國內市場份額。

Disc balling machines are used for iron ore balling. They are one of the main kinds of supporting equipment in various pelletizing plants. Disc balling machines are designed and developed after absorption of advanced experience both at home and abroad. The products adopt electric rotary scraper and scraping disc side particle balls which have strong adaptability. The inclination angle and rotating speed can both be adjusted and the structure is of brief counter flow type, which is easy for installation and maintenance. They are very productive and highly efficient. Their main technical indicators are in the leading position in China and occupy 80% of the domestic market share.

本廠可根據用戶需要,設計制造不同規格型號的圓盤造球機。

Our factory can design and manufacture disc balling machines of different specifications and models according to the needs of users.

1、用途:圓盤造球機粒度均勻,強度好,生球合格率率,可廣泛應用于冶金、建材、礦山、化工及其他部門。

1. Application: The disc balling machines have uniform particle size, high strength, and high qualification rate of green pallet. They are widely applied in metallurgy, building material, mining, chemicals and other sectors.

2、結構及特點:主傳動部分主要分為主軸套筒結構,回轉支撐無軸傳動,對傘齒輪傳動等幾種結構形式。主軸套筒結構承載能力大,隨不均勻載荷能力強,適合在冶金口等各類燒結球團生產中使用;回轉支撐無軸傳動形式結構簡單,傳動平穩,但成本較高;傘齒輪傳動結構成本低、適合規格較小,產量較低的圓盤造球機。

2. Structure and Characteristics: The main driving parts are mainly of main shaft sleeve structure, slewing ring shaftless transmission structure, and bevel gear transmission structure. The main shaft sleeve structure has strong bearing capacity and strong ability of bearing uneven load. They are suitable to be used in the production of various sinter balls such as metallurgy. The slewing ring shaftless transmission structure is characterized by simple structure, smooth transmission, and high costs. The bevel gear transmission structure is characterized by low cost which are suitable for disc balling machine of small specification and low yield.

盤面刮刀有固定式和旋轉式,固定刮刀結構簡單、成本低廉;旋轉刮刀提高成球率及均勻性,生產效率高。盤面傾角和運轉速度可根據制粒工藝要求(粒度的大小、產量的高低等)

Disc face scrappers are divided into stationary ones and rotary ones. The stationary ones is simple in structure and low in cost. The rotary ones however can increase granulation rate, improve uniformity and enjoy high production efficiency. The inclination angle and rotation speed can be designed according to the requirements of granulation technology (such as granule size, productivity, etc).

3、我廠生產造球機設計能力達Φ8m,現已生產過的****造球機Φ6m。

3. The designed capacity of balling mills manufactured by our factory reaches Φ8m. The largest balling mill already manufactured is Φ6m.

4、主要圓盤造球機的技術參數

4. Technical parameters of main disc balling machine

技術參數

| 規格名稱 | ф7000 | ф6000 | ф5500 | ф5000 | ф4500 | ф4200 | ф3500 | ф3000 | |

| 造球盤直徑 | m | 7 | 6 | 5.5 | 5 | 4.5 | 4.2 | 3.5 | 3 |

| 造球盤邊高 | m | 0.7 | 0.7 | 0.7 | 0.6 | 0.6 | 0.45 | 0.45 | 0.4 |

| 造球盤轉速 | r/min | 4~5 | 7~8.5 | 7~8.5 | 2~8 | 3~9 | 8.41 | 10.5 | 12.3 |

| 造球盤傾角 | (0) | 40~55 | 40~55 | 40~55 | 40~55 | 40~55 | 40~55 | 40~55 | 40~55 |

| 生產能力 | t/h | 50~60 | 30~45 | 25~40 | 20~30 | 15~20 | 12 | 5~10 | 3~7 |

| 電機功率 | kw | 160 | 110 | 110 | 55 | 55 | 55 | 30 | 30 |

| 刮刀 | 旋轉式 | 旋轉式 | 旋轉式 | 旋轉式 | 旋轉式 | 固定式 | 固定式 | 固定式 | |

| 參考重量 | t | 61.5 | 44.2 | 43.3 | 27 | 26 | 16 | 12.5 | 10.5 |